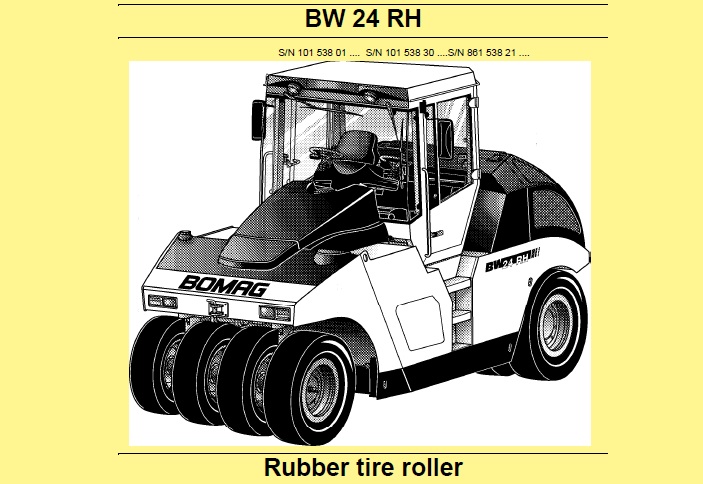

Download Service Repair Manual For Bomag BW 24 RH Rubber Tire Roller.

Publication No. 00891504 10/2013

This Service Manual offers all the Service and Repair Information for Bomag BW 24 RH Rubber Tire Roller. With this in-depth & highly detailed manual you will be able to work on your vehicle with the absolute best resources available, which will not only save you money in repair bills but will also help you to look after your business. The information on this manual covered everything you need to know when you want to repair or service Bomag BW 24 RH Rubber Tire Roller.

Models Covered:

Bomag BW24 RH Rubber Tire Roller

S/N 101 538 01 …. S/N 101 538 30 ….S/N 861 538 21 ….

This manual is INSTANT DOWNLOAD. It means no shipping cost or waiting for getting a CD package for several days. you will receive this manual today via instant download on completion of payment via our secure payment processor.

Manual Contents:

1.1 Introduction

Safety regulations

General repair instructions

Tightening torques

Rubber tire roller

Technical data

4.1 General notes on maintenance

4.2 Fuels and lubricants

4.3 Table of fuels and lubricants

4.4 Running-in instructions

4.5 Maintenance table

5.1 Level sensor in diesel tank (R03)

5.2 Differential pressure switches hydraulic oil filter, B21and B22

5.3 Brake oil temperature switch, B148

5.4 Brake pressure switches, B12 and B102

5.5 Float switch in water tank, B33

5.6 Oil pressure switch, B06

5.7 Coolant temperature switch, B152

5.8 Sensor (B124), water in fuel filter

5.9 Air filter vacuum switch, B03

5.10 Charge control light, operating hour meter

5.11 Fuel preheating, R79

5.12 Glow plugs

5.13 Engine solenoid to shit down the engine, Y13

5.14 Boost fuel solenoid valve, Y01

5.15 Engine monitoring

5.16 Batteries

5.17 Battery service, checking the main battery switch

5.18 Main battery switch

5.19 Generator

5.20 Replacing the voltage regulator

5.21 Electric starter

Overview of electric components

5.23 Fuse, cabin

5.24 Fuses

5.25 Main battery fuse

5.26 Modules

7.1 Steering column locking module, A100

8.1 Speedometer module

Overview

9.2 Hydraulic circuit

Travel pumps, A4VG105 DA

9.4 Troubleshooting axial piston pumps

External gear pumps

Travel motor, A6VM 107HA2R1

9.7 Trouble shooting, variable displacement axial piston motor

Steering valve

9.9 Travel circuit

9.10 Steering circuit

9.11 Cooling and cross-flushing of the brake housing

9.12 Edge cutter

9.13 Check the hydraulic oil level

9.14 Replace hydraulic oil and breather filter.

9.15 Replace hydraulic oil filter

9.16 Replacing the bypass filter

Overview

Brake system

10.3 Stopping the machine, operating the parking brake

10.4 Driving the machine / braking the machine

10.5 Multi-disc brake, function test

10.6 Towing in case of an engine failure

Overview

Pneumatic system

11.3 Operating the tire inflation system

11.4 Draining the air pressure vessel

11.5 Change the air drier for the brake system

11.6 Check the supply lines for the compressor

12.1 Description of engine

12.2 Lubrication oil circuit TCD 2012 / 2013

12.3 Coolant circuit TCD 2012 / 2013

Exhaust gas recirculation

12.5 Adjust the valve clearance

12.6 Check the engine oil level

12.7 Changing engine oil and oil filter

12.8 Change the fuel filter, bleed the fuel system

12.9 Check, clean the water separator

12.10 Checking the coolant level

12.11 Check the anti-freeze concentration and the condition of the coolant

12.12 Replacing the coolant

12.13 Clean the cooling fins on engine and hydraulic oil cooler

12.14 Checking ribbed V-belts and compressor V-belts

12.15 Replacing ribbed V-belt and idler pulley

12.16 Air filter maintenance

12.17 Replace the injection valves

12.18 Replace crankcase ventilation valve

12.19 Check the engine mounts

12.20 General trouble shooting chart TCD 2012 / 2013

12.21 Special tools, Deutz engine (TCD 2012 2V)

13.1 Physical basics

13.2 Refrigerant R134a

13.3 Compressor oil / refrigeration oil

13.4 Working principle of the air conditioning system

13.5 Monitoring devices

13.6 Description of components

13.7 Measuring the compressor oil level

13.8 Checking the magnetic clutch

13.9 Inspection and maintenance work

13.10 Checking, replacing the refrigerant compressor V-belt

13.11 Service the air conditioning

13.12 Drying and evacuation

13.13 Emptying in case of repair

13.14 Leak test

13.15 Filling instructions

13.16 Trouble shooting in refrigerant circuit, basic principles

13.17 Trouble shooting, refrigerant circuit diagram

13.18 Trouble shooting procedure

Steam table for R134a

15.1 Repair overview for front axle

15.2 Dismantling the front axle

15.3 Assembling the front axle

Total Pages: 606

This manual can be used by anyone from a first time owner/amateur to a professional technician. Even the most novice mechanic can also easily follow the step-by-step guides which are made simple by the illustrations and drawings. Keep this manual handy and use it often. Performing routine, preventive maintenance will save you time & money by helping to prevent premature failure and unnecessary repairs.

Your will receive a download link in no time after your payment is completed successfully. So please make sure your email address is correct. Don’t Forget to Check Spam / Junk if can’t find the new message in your email inbox immediately.

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English