Download Service Repair Manual For Bell B35D & B40D 6×6 ARTICULATED DUMP TRUCK.

Document Part Number 872092

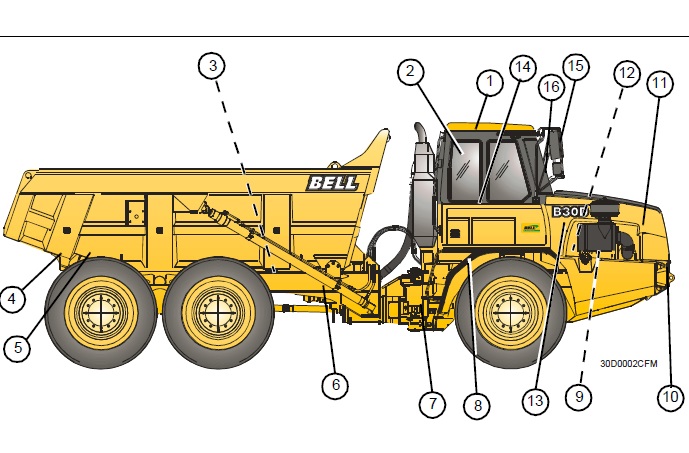

This Service Repair Manual offers all the service and repair information for Bell B35D & B40D 6×6 ARTICULATED DUMP TRUCK. With this in-depth & highly detailed manual you will be able to work on your vehicle with the absolute best resources available, which will not only save you money in repair bills but will also help you to look after your business. The information on this manual covered everything you need to know when you want to repair or service on Bell B35D & B40D 6×6 ARTICULATED DUMP TRUCK.

Models Covered:

B35D 6X6 (E359835)

B40D 6X6 (E409840)

This manual is INSTANT DOWNLOAD. It means no shipping cost or waiting for getting a CD package for several days. you will receive this manual today via instant download on completion of payment via our secure payment processor.

Service Manual Contents:

SAFETY

Specification

Safety Features

Material Safety Data Sheets (MSDS)

Unauthorised Modifications of the Roll Over Protective Structure (ROPS) and the Falling Objects Protective

Structure (FOPS)

Noise Emission Levels

General Safety

USER’S INFORMATINON FEEDBACK FORM

CHAPTER 1. WHEELS

REMOVAL AND INSTALLATION

CHAPTER 2. AXLES AND SUSPENSION SYSTEMS

SECTION 1. REMOVAL AND INSTALLATION

AXLES

SECTION 2. DIFFERENTIAL OR BEVEL DRIVE

AXLE DIFFERENTIAL

SECTION 3. INPUT DRIVE SHAFTS AND U-JOINTS

DRIVE SHAFTS

SECTION 4. AXLE MOUNTING PARTS

SECTION 5. AXLE SHAFTS, BEARINGS AND REDUCTION GEARS

AXLE OUTBOARD PLANETARIES

CHAPTER 3. TRANSMISSION

SECTION 1.REMOVAL AND INSTALLATION

SECTION 2. INPUT DRIVE SHAFTS AND U-JOINTS

REMOVE AND INSTALL TRANSMISSION-TO-TRANSFER CASE DRIVE SHAFT

SECTION 3. GEAR, SHAFT AND POWER SHIFT CLUTCHES

SECTION 4. HYDRAULIC SYSTEM

CHAPTER 4. ENGINE

SECTION 1. REMOVAL AND INSTALLATION

ENGINE

SECTION 2. CRANKSHAFT, MAIN BEARINGS AND FLYWHEEL

INSTALL ENGINE ON REPAIR STAND

CRANKSHAFT AND MAIN BEARING FAILURE ANALYSIS

CRANKSHAFT OIL SEALS

FLYWHEEL

CRANKSHAFT

GRINDING GUIDELINES

GRINDING SPECIFICATIONS

BLEED ENGINE OIL CIRCUIT AFTER MAJOR OVERHAUL

SECTION 3. CAMSHAFT AND TIMING GEAR TRAIN

CAMSHAFT

SECTION 4. CYLINDER BLOCK, LINERS, PISTONS AND RODS

LINER, PISTON AND ROD ANALYSIS

SECTION 5. LUBRICATION SYSTEM

REMOVE AND INSTALL OIL FILTER HOUSING

REMOVE, INSPECT, AND INSTALL ENGINE OIL COOLER

REMOVE AND INSTALL OIL PAN

REMOVE, INSPECT AND INSTALL PISTON COOLING ORIFICES

REMOVE AND INSTALL ENGINE OIL PUMP

REMOVE AND INSTALL OIL PRESSURE RELIEF VALVE

SECTION 6. CYLINDER HEAD AND VALVES

CYLINDER HEAD AND VALVES FAILURE ANALYSIS

REMOVE AND INSTALL VALVE COVER

SECTION 7. EXHAUST SYSTEM

SECTION 8. FUEL INJECTION SYSTEM

REMOVE AND INSTALL HAND PRIMER PUMP

REMOVE AND INSTALL FUEL SUPPLY PUMP

REMOVE AND INSTALL ELECTRONIC UNIT INJECTOR (EUI)

REMOVE AND INSTALL FUEL DELIVERY NOZZLE

SECTION 9. AIR INTAKE MANIFOLD SYSTEM

SECTION 10. TURBOCHARGER

SECTION 11. COOLING SYSTEM

SECTION 12. THERMOSTATS, HOUSING ANDWATER PIPING

THERMOSTATS AND HOUSING

CHAPTER 5. ENGINE AUXILIARY SYSTEM

SECTION 1. COOLING SYSTEM

FAN BELT

RADIATOR

SECTION 2. INTAKE SYSTEM

AIR INTAKE SYSTEM

REMOVE AND INSTALL CHARGE AIR AFTERCOOLER

SECTION 3. EXTERNAL EXHAUST SYSTEM

SILENCER AND EXHAUST PIPES

SECTION 4. ENGINE MOUNTING

RUBBER MOUNTINGS

SECTION 5. EXTERNAL FUEL SUPPLY SYSTEM

HAND PRIMER PUMP3

PRIMARY FUEL FILTER (WATER SEPARATOR)

FUEL TANK

CHAPTER 6. CONNECTOR DRIVE (FLEXPLATE)

SECTION 1. ELEMENTS

CHAPTER 7. TRANSFER DRIVE

SECTION 1. REMOVAL AND INSTALLATION

REMOVE AND INSTALL TRANSFER CASE

SECTION 2. GEAR SHAFTS AND BEARINGS

TRANSFER CASE

CHAPTER 8. STEERING SYSTEM

SECTION 1. SECONDARY STEERING

SECONDARY STEERING PUMP

SECTION 2. HYDRAULIC SYSTEM

STEERING VALVE

CHAPTER 9. SERVICE BRAKES

SECTION 1. ACTIVE ELEMENTS

SERVICE BRAKES B35D

SECTION 2. HYDRAULIC SYSTEM

BLEED SERVICE BRAKE HYDRAULIC SYSTEM

CHAPTER 10. PARK BRAKE

SECTION 1. ACTIVE ELEMENTS

PARK BRAKE

CHAPTER 11. FRAME AND SUPPORTING STRUCTURE

SECTION 1. FRAME INSTALLATION

WELDING ON MACHINE

SEPARATE FRONT AND REAR FRAMES

ARTICULATION FRAME

CHAPTER 12. OPERATOR’s STATION

SECTION 1. CAB

CAB MOUNTINGS

SECTION 2. SEAT AND SEAT BELT

OPERATOR’S SEAT

SECTION 3. HEATING AND AIR CONDITIONING

REFRIGERANT CAUTIONS AND PROPER HANDLING

R134a REFRIGERANT OIL INFORMATION

CHAPTER 13. SHEET METAL AND STYLING

SECTION 1. BONNET OR ENGINE ENCLOSURE

BONNET

CHAPTER 14. MAIN HYDRAULIC SYSTEM

SECTION 1. HYDRAULIC SYSTEM

MAIN HYDRAULIC PUMP

CHAPTER 15. PNEUMATIC SYSTEMS

SECTION 1. PUMPS AND DRIVES

AIR COMPRESSOR

SECTION 2. CONTROL VALVES

PNEUMATIC MANIFOLD

SECTION 3. RESERVOIR, FILTER AND TRAP

AIR UNLOADER VALVEWITH INTEGRAL AIR DRYER

SECTION 4. CYLINDERS

REMOVE AND INSTALL EXHAUST BRAKE AIR CYLINDER

CHAPTER 16. HAULAGE DEVICE

SECTION 1. FRAMES

BODY

SECTION 2. HYDRAULIC SYSTEM

BODY LIFT CYLINDER

CHAPTER 17. DEALER FABRICATED TOOLS

SECTION 1. TOOLS

DFT1178 LIFTING TOOL

DFT1181 BUSHING DRIVER

DFT1186 BUSHING DRIVER

DFT1185 SUPPORTS

DFT1187 BEARING DRIVER

DFT1188 BEARING DRIVER

DFT1189 SPANNERWRENCH

DFT1194 BEARING PULLER

DFT1199 BUSHING PUSHER

DFT1200 BUSHING DRIVER

DFT1196 BUSHING DRIVER

Total Pages: 394

This manual can be used by anyone from a first time owner/amateur to a professional technician. Even the most novice mechanic can also easily follow the step-by-step guides which are made simple by the illustrations and drawings. Keep this manual handy and use it often. Performing routine, preventive maintenance will save you time & money by helping to prevent premature failure and unnecessary repairs.

Your will receive a download link in no time after your payment is completed successfully. So please make sure your email address is correct. Don’t Forget to Check Spam / Junk if can’t find the new message in your email inbox immediately.

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English